Cold Storage Refrigeration

Ammonia refrigeration has been the backbone of the cold storage and food processing industries since the early 1900s. Many years ago, the food and beverage industry embraced ammonia refrigeration. The economic advantages alone made it the refrigerant of choice for cold storage facilities and food processing facilities as well as the dairy and meat-packing industries. Ammonia refrigeration is the most cost effective and energy efficient method of processing and storing frozen and refrigerated foods.

Ammonia was among the early refrigerants used in mechanical systems, and it’s the only one of the early refrigerants to secure a lasting role as a refrigerant. The basic design of the vapor compressor refrigeration system, using ammonia as a refrigerant in a closed cycle of evaporation, compression, condensation, and expansion, has changed very little since the early 1900s.

The Need For Ammonia Detection:

Ammonia refrigeration systems can and do leak or malfunction at any point (in time and in the system) leaving a cold storage facility exposed to massive inventory loss and potential human life loss. Even small leaks can contaminate an entire lot or batch of inventory rendering it as “unsuitable” for resale. It should be noted that these small leaks will eventually turn into larger leaks that can lead to catastrophic events. Every year, people are injured and inventory is lost from preventable “ammonia related” accidents.

“You will be hard pressed to find an ammonia detection system as economical as this.”

For more sophisticated ammonia detection and monitoring of your cold storage facility, Pacific Sentry can develop turnkey sensing solutions that minimize the involvement of the operator or safety manager. Imagine being able to constantly monitor your facility from any remote location. If a leak develops, an alert notice is automatically sent directly to your mobile phone or email so that corrective action can immediately be taken. The quicker an ammonia leak is identified, the greater chance you have to save inventory and potentially, human life.

The Solution

With Pacific Sentry’s Ammonia Leak Detection Pipe Thread Tape, not even the smallest pin-hole leak will go undetected. Every union, fitting, and joint within the system can be actively monitored to ensure no leak has developed or is developing. A quick glance at the color of the Ammonia Leak Detection Tape, even at a distance, will tell you if your ammonia system is sealed and secure or if a leak is present. Not only does it tell you that you have an ammonia leak, but it also allows you to pin-point the EXACT location of the leak – down to the smallest, microscopic pin-hole fracture. You no longer have to walk around taking measurements with an electronic ammonia meter or smoke stick guessing where the leak may be; a simple visual inspection of the Ammonia Leak Detection Tape will provide you the information you need to determine if there is a leak and where exactly that leak is.

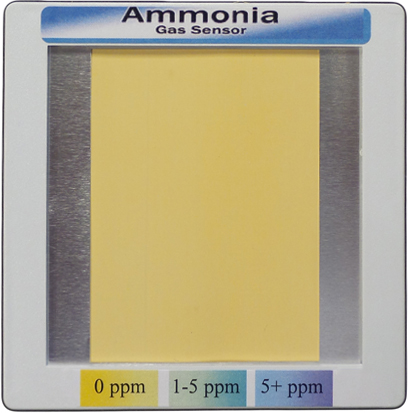

To simply detect if there is any ammonia in a cold room, the Ammonia Gas Sensor provides the best and most economical solution. Similar to the Ammonia Leak Detection Tape, the Ammonia Gas Sensor allows for an easy-to-view and Ammonia Gas Sensor quick visual inspection of the sensor to determine if ammonia is present in a refrigerated room. If the color of the sensor turns green/blue, ammonia is present; if the color remains canary yellow, no ammonia is present. With a color reference chart, the Ammonia Gas Sensor also provides a means to determine the ppm’s ammonia concentration which is useful for assessing how bad a leak may be.

To simply detect if there is any ammonia in a cold room, the Ammonia Gas Sensor provides the best and most economical solution. Similar to the Ammonia Leak Detection Tape, the Ammonia Gas Sensor allows for an easy-to-view and Ammonia Gas Sensor quick visual inspection of the sensor to determine if ammonia is present in a refrigerated room. If the color of the sensor turns green/blue, ammonia is present; if the color remains canary yellow, no ammonia is present. With a color reference chart, the Ammonia Gas Sensor also provides a means to determine the ppm’s ammonia concentration which is useful for assessing how bad a leak may be.

For testing ammonia that may have leaked into your industrial coolant(s), Pacific Sentry’s Ammonia Test Strips for Industrial Coolants are a cost-effective and efficient solution for monitoring and maintaining cooling systems. Regular testing (at least once a month) helps ensure ammonia-based refrigeration systems are functioning properly and not leaking ammonia. This also gives your company added insurance against costly losses and downtime.

For testing ammonia that may have leaked into your industrial coolant(s), Pacific Sentry’s Ammonia Test Strips for Industrial Coolants are a cost-effective and efficient solution for monitoring and maintaining cooling systems. Regular testing (at least once a month) helps ensure ammonia-based refrigeration systems are functioning properly and not leaking ammonia. This also gives your company added insurance against costly losses and downtime.

You will be hard pressed to find an ammonia detection system as economical as this.

For more sophisticated ammonia detection and monitoring of your cold storage facility, Pacific Sentry can develop turnkey sensing solutions that minimize the involvement of the operator or safety manager. Imagine being able to constantly monitor your facility from any remote location. If a leak develops, an alert notice is automatically sent directly to your mobile phone or email so that corrective action can immediately be taken. The quicker an ammonia leak is identified, the greater chance you have to save inventory and potentially, human life.

See All Products

If you would like to know more about what we do, or have other general inquiries, please call (425)-229-9701 and talk directly to a representative. Custom fabrication requests are also welcomed; call or email info@pacificsentry.com for details. We will gladly work with you to design the best solution that meets your needs.